Industrial Hydrogen Generators (range from 20 – 200 Nm3/h H2)

Fuels: NG, methane, LPG, propane, biogas

Capacity: 20-200 Nm3/h H2 production

Applications: High purity hydrogen production suitable for automobile refueling stations, fat hydrogenation plants, glass and electronics industry, PEM fuel cells.

Helbio has developed a family of Hydrogen Generators designed to meet demanding requirements of small-scale hydrogen supply, using fuels such as Natural Gas, L.P.G or Biogas. The system offers clean, quiet and efficient hydrogen generation under continuous operation with long service intervals. The standards systems HHG-20, HHG-50, HHG-100 and HHG-200 generate normally 20,50,100 and 200 Nm3/h of H2 respectively. Hydrogen purity ranges from 99,9% to 99,999% upon customer request. Natural Gas can be obtained from the existing network. Biogas can originate from various sources such as astewater treatment plants, landfills or organic waste from industry and/or households. System design and construction complies with all relevant international standards and E.C. directive (97/23 EC, 94/9 EC, 2004/108 EC, EN13445). CE marking is available upon customer request.

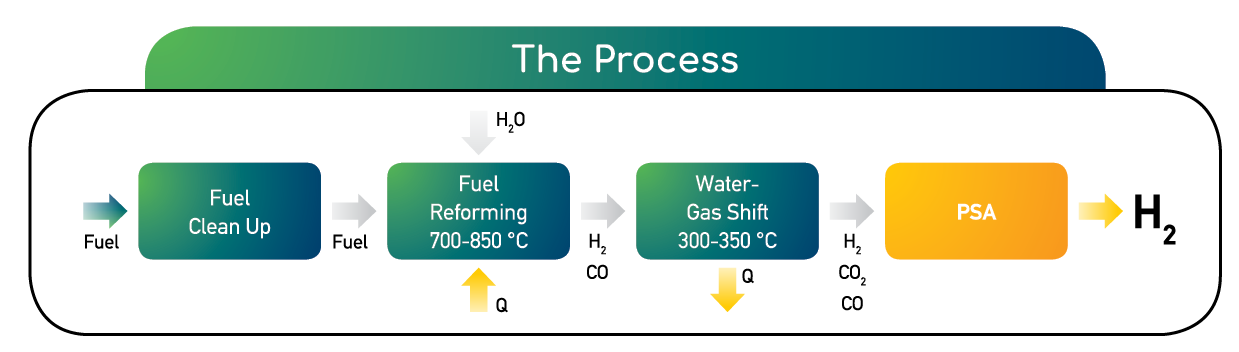

The unit is composed of the following subsystems:

Subsystem 1: Natural gas compressor[1], natural gas purification unit, reforming reactor, shift reactor, steam generator, associated heat exchangers and peripherals.

Subsystem 2: Pressure Swing Adsorption (PSA) unit for gas purification.

Subsystem 3: Control hardware with HMI interface and control software.

The process diagram of Helbio`s Hydrogen Generators can be seen in the following picture.

[1] Not necessary if inlet pressure of natural gas is ≥9 bar(g).